This goes back to May 2019 at the Sculpture Workshops. I would normally blog when the piece is finished, but things are on hold at present.

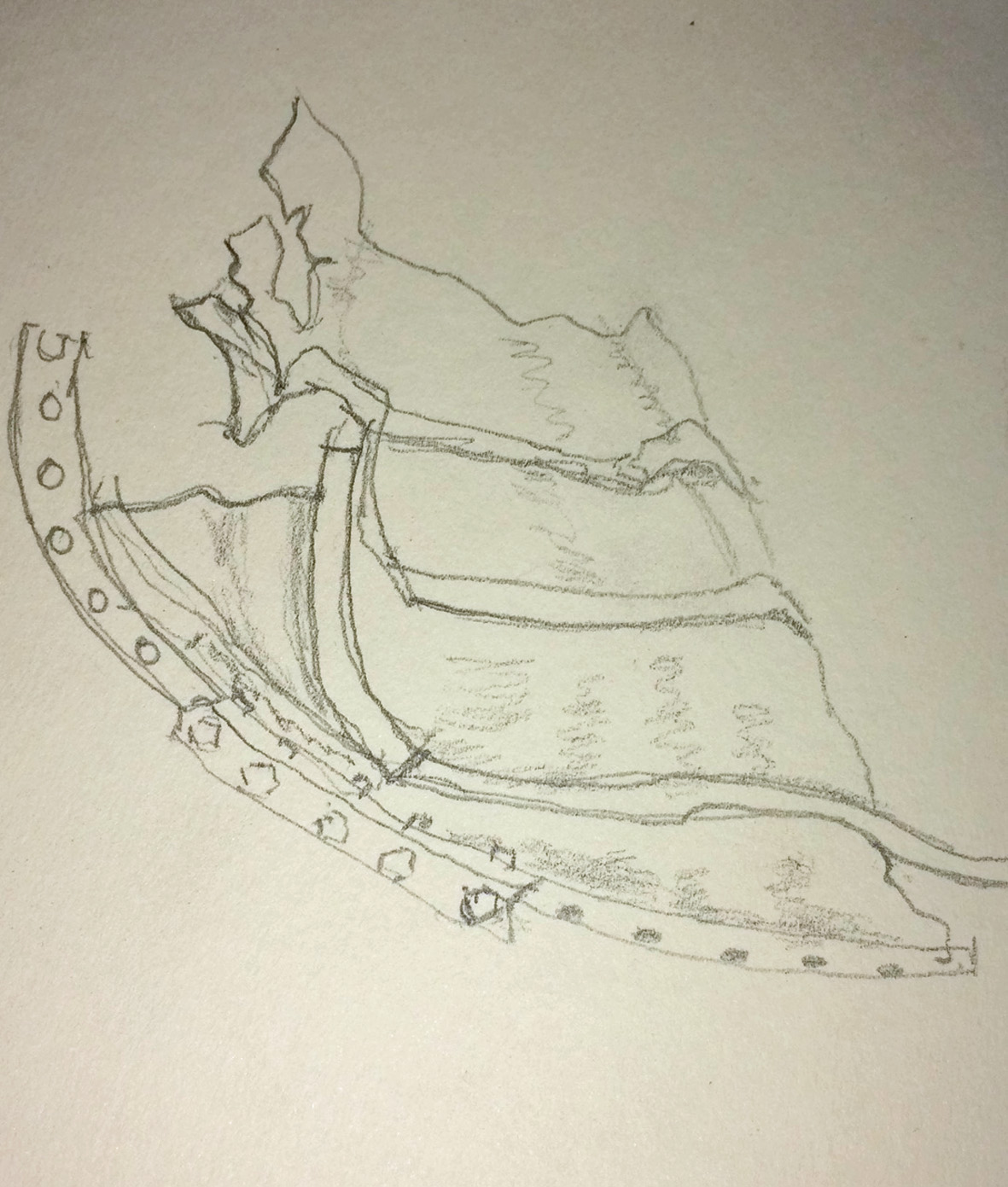

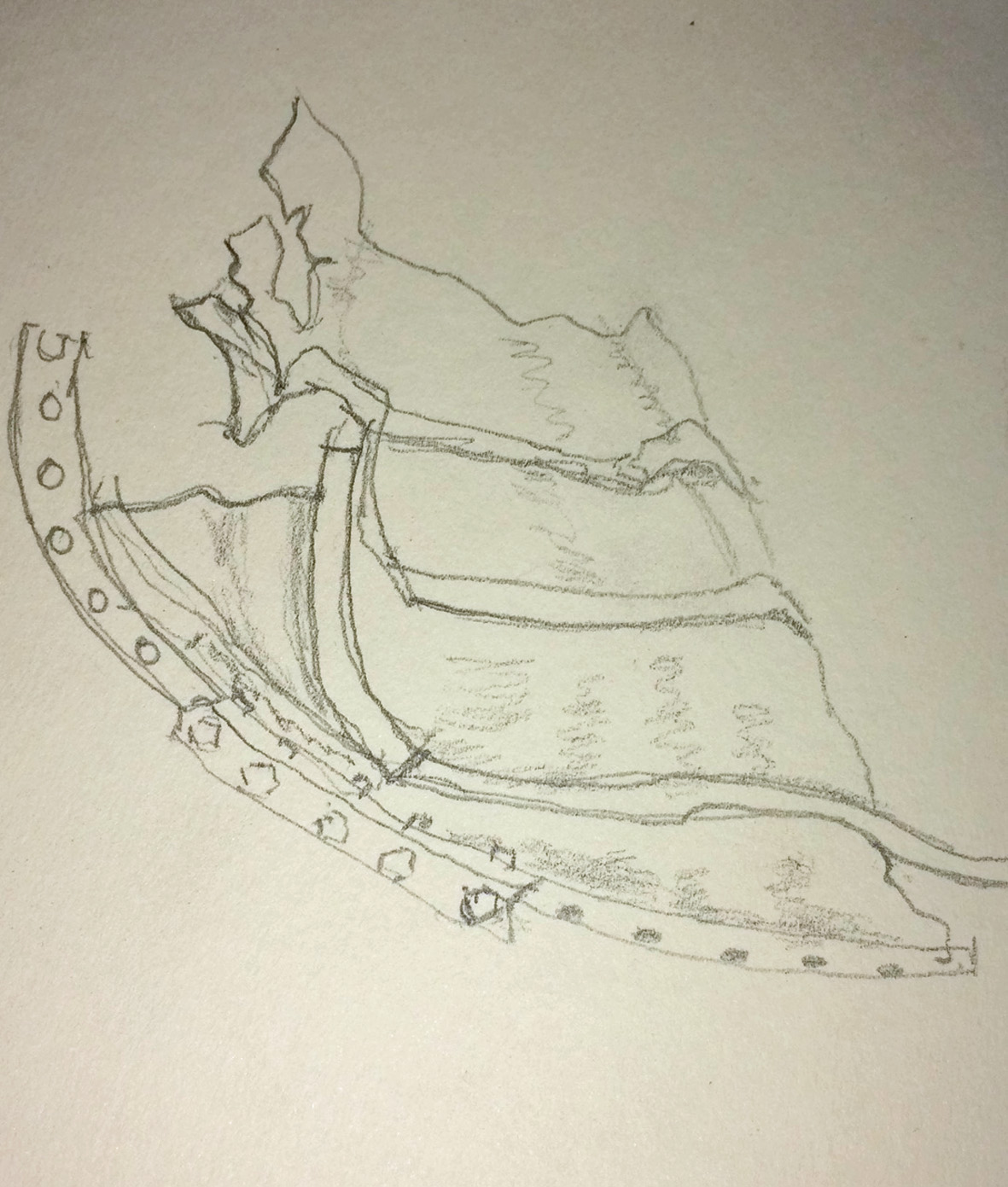

I discovered Italian block (thanks Eden) and made the beeswax model (above) for the main part of a commissioned piece remembering the heroes at Dunkirk and La Panne. The design is based on a torpedoed submarine in the Imperial War Museum in London.

I made a clay model and then took a beeswax cast from the clay. The top photo is the wax cast which has been sprued (adding runners for the metal, risers for escaping air and a funnel for pouring in the metal)

The italian block is made by making a flask of chicken wire around the wax, which is stood in pouring position in the flask.

This is draped in hessian soaked in plaster to form a plaster flask surrounding the wax,

The flask is then filled with the plaster mixture to create a solid block around the wax and dried.

The block mould is then heated slowly in a kiln overnight to melt out the wax and fire the plaster mix.

The mould is ready to be poured whilst still hot, so that it doesn’t fracture with the shock of the molten metal. This piece was poured at the end of May.

This traditional method can be used for bronze, silver and lower melt metals, but not for iron.

The Sculpture Workshop is reviewing its safety procedures and stopped all Italian block firing in summer 2019, pending the outcome of this review. Plans are in hand to remodel the metal workshops and I hope that when this happens I can explore Italian block further. I really like the method as offering great scope for design whilst being pretty sustainable and low tech.

The process was much the same, but it needed to be made in two pieces because of the limit on the crucible size in the foundry. The mould was taken from the original wax and then a clever ruse with carpeting provided for the thickness of the metal. The photo shows taking the mould from the wax which has just been used for the iron lintel mould.

The process was much the same, but it needed to be made in two pieces because of the limit on the crucible size in the foundry. The mould was taken from the original wax and then a clever ruse with carpeting provided for the thickness of the metal. The photo shows taking the mould from the wax which has just been used for the iron lintel mould.

The workshop took us through the marionette carving, scenery painting, theatre painting, Marionette dressing and using the marionettes to tell our story. Above is a photo of the workshop with everyone working.

The workshop took us through the marionette carving, scenery painting, theatre painting, Marionette dressing and using the marionettes to tell our story. Above is a photo of the workshop with everyone working. Starting with four blocks of wood, I carved the heads of my four puppets for a show based on the Snow Queen. Other blocks were carved for the hands, shoes and legs. Everything was then painted and clothes made. Mirek Trejtnar, the workshop leader, assembled the puppets and they were ready for the theatre. Lots of people helped and advised, including Marcella, Vaclav and Sota.

Starting with four blocks of wood, I carved the heads of my four puppets for a show based on the Snow Queen. Other blocks were carved for the hands, shoes and legs. Everything was then painted and clothes made. Mirek Trejtnar, the workshop leader, assembled the puppets and they were ready for the theatre. Lots of people helped and advised, including Marcella, Vaclav and Sota.

Thanks to Scottish Sculpture Workshop tech team and George Beasley.

Thanks to Scottish Sculpture Workshop tech team and George Beasley.

A sea water patinated bowl went to a new home as did a sea drift necklace.

A sea water patinated bowl went to a new home as did a sea drift necklace.